When news of the coronavirus pandemic started to hit close to home (in the U.S.), it became clear that acquiring face masks and shields was a challenge. In many areas, personal protective equipment, or PPE, were in short supply. It was vital that our frontline workers had the protection they needed to keep themselves and their patients safe. In addition, safety was an issue for daily activity by ordinary citizens.

Due to stay-at-home directives that limited regular routines in the hopes of ‘flattening the curve’, Boxlight employees in California and Washington redirected their energy to help with PPE production, using 3D printer technology.

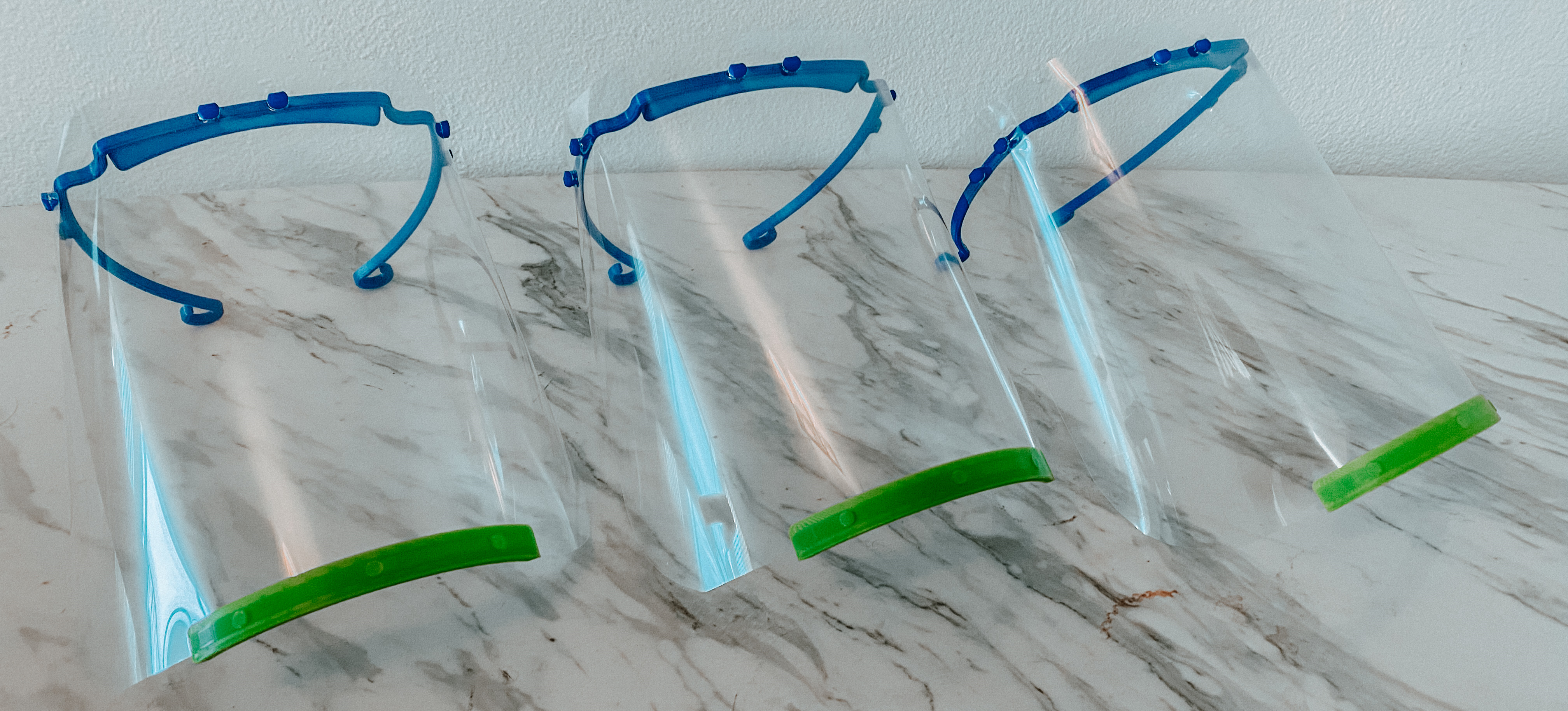

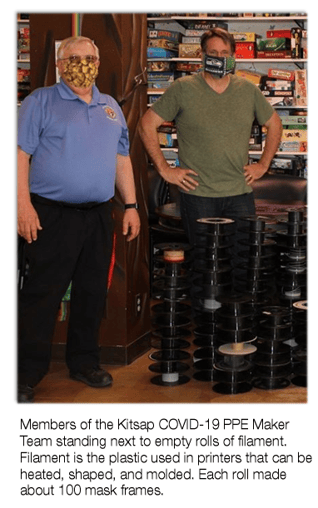

Tim Anderson, Service Technical Supervisor based out of the Boxlight Service Department West (Poulsbo, WA), immediately stepped in to help print frames that were part of a face mask shield kit. A local 3D printer group – the Kitsap COVID-19 PPE Maker Team -- pulled together to make face shield kits which included a frame elastic strap for the head band, the plastic face shield, and a face shield support.

“All of a sudden I was working from home and realized I was in a position to help!” says Anderson. “It’s often I’m using my 3D printer for personal use, building parts for miniature race boats. So, to switch gears and focus on mask supplies was easy.” Anderson used his 3D printer to make approximately 100 of the frames, taking a little over an hour to print each frame. Anderson remarks, “Good thing the printer is ‘start and let it run until it’s done!’”

With healthcare professionals wearing masks nearly constantly during their working hours, many were also experiencing ear pain due to the strain.

So, in addition to straps, the group also made a number of ‘ear savers’ to keep the straps from being on the ear all the time. In just over four weeks, the group made more than 8500 face shield mask kits. Currently, they have stopped the mass production of the shields, but are still filling requests from dentists and other health care providers.

Meanwhile, in California, Braydon Moreno, Director of STEM Solutions at Boxlight, found himself in a similar situation. “All of a sudden I’m locked up in my home in San Diego. We are in the business of 3D printing so printing shields for frontline workers was really a part of the norm for me,” says Moreno. “I began printing them out of my home with a team of business and industry friends. But the need outgrew our availability to fund them, so we started a GoFundMe page that raised close to $5000 immediately.” To see time-lapse video of the printer in action, click here: Faceshield PPE

Moreno describes the response as “incredible,” noting that “smaller hospitals are in need more than ever.” He continues, “It seems like the supply and logistics issues around PPE is starting to get solved as the request for the equipment is not as high. There was a surge for about 6 weeks where it was difficult for most hospitals and clinics to get PPE. Now, it’s back to business!”

To date, Moreno and his team have donated over 2000 3D-printed face shields to 29 different hospitals and clinics around the country.

As we slowly begin a return to ‘normal’, the creativity and ingenuity that so many have shown during this time highlights what we all know – technology can be used for an incredible amount of good. We are thankful to all frontline workers who have done so much to keep our communities going.

Boxlight offers 3D printers and STEM curriculum for schools, with kits to enhance learning and engage students in exploration, critical thinking, and problem solving. If you are an educator and would like to learn more about our 3D printers and STEM kits, please see: robo3d.com.